Geothermal Heat Loop Systems

Key Takeaways

- Geothermal heat loop systems utilize the earth’s consistent below ground temperatures to offer economic and efficient heating or cooling for structures large and small worldwide.

- Closed and open loop systems utilize distinct heat exchange techniques, where closed loops circulate a fluid through sealed pipes, and open loops draw directly from groundwater sources.

- Proper design, including geological assessment and accurate sizing, is essential to ensure optimal performance and long-term reliability of geothermal systems.

- By combining with existing or new HVAC, you can improve energy efficiency even more, and routine maintenance can prolong system longevity and performance.

- Geothermal systems are incredibly environmentally friendly, helping to reduce greenhouse gas emissions and generating major cost savings in the long-term, particularly when government incentives come into play.

- Continued innovation in geothermal technology is bringing these systems within reach and making them more efficient, opening up new possibilities for adoption in cities and remote locations across the globe.

Tapping the constant heat of the earth. They circulate heat back and forth between a building and the ground via pipes buried underground. Because the ground maintains a relatively constant temperature year-round, it helps to keep the indoor space comfortable regardless of the weather. Geothermal heat loops tend to be closed or open loop systems, and each functions optimally in different environments. Homeowners and businesses pick them for their energy efficiency and cost savings over time. They typically reduce greenhouse gases and decrease our dependence on fossil fuels. To illustrate the mechanics of geothermal heat loop systems as well as the advantages and limitations they present, the following discussion addresses the fundamentals and practical applications.

System Fundamentals

Geothermal heat loop systems use the earth’s core principle: steady underground temperatures. These systems circulate heat from between the ground and a building via a heat pump, ground loop, and distribution network. The primary benefit arises from the ground’s temperature stability throughout the seasons, typically around 13°C (55°F), which allows the system to more efficiently maintain comfortable indoor temperatures.

1. The Principle

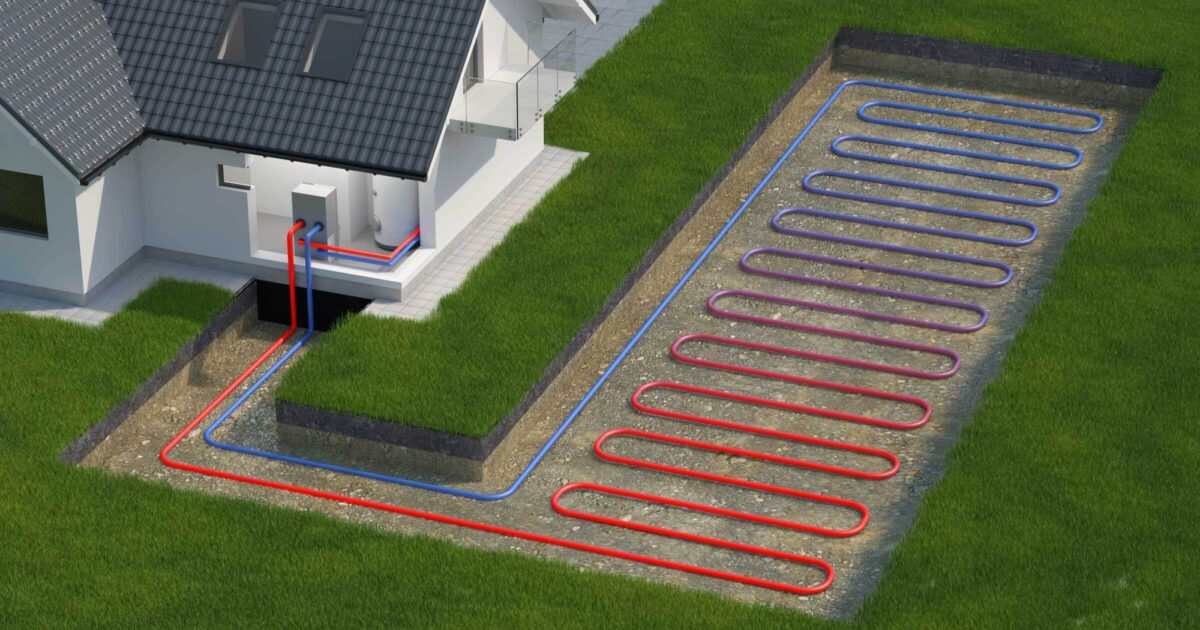

Geothermal systems transfer heat between the building and the earth. They employ pipes buried in the ground —ground loops — containing a fluid that either absorbs or dissipates heat. This is controlled by a heat pump, which extracts energy from the ground in winter and deposits it back into the earth during the summer for cooling.

The heat pump’s components—compressor, condenser, expansion valve and evaporator—assist in moving heat from point A to point B, similarly to a typical air conditioner, with the added advantage of ground temperatures that remain relatively stable through seasonal changes. This consistency keeps the system from kicking on so frequently, increasing efficiency. Most geothermal heat pumps have a COP of 3 to 4.5, so they can provide three to five times more energy than they consume.

To use the ground’s consistent temperature is to depend less on fossil fuels, emit less greenhouse gases, and harness a sustainable way to regulate indoor environments.

2. Closed Loops

Closed loop systems circulate a heat transfer fluid through sealed pipes underground. This fluid collects heat from the soil in the winter or surrenders it in the summer. It operates very similarly to hydronic heating, with water continually circulating.

These tanks are dependable because the fluid never combines with external water, reducing pollution risks. Closed loops can be installed horizontally, vertically or even in a pond, based on space and soil conditions. Direct expansion is one, with three other major closed loop alternatives utilized globally.

Installation is a delicate process—soil, ground moisture, space all important. Deep vertical loops are great for small yards, while wide open spaces can embrace horizontal setups.

3. Open Loops

Well, an open loop utilizes groundwater as a direct heat source or sink. Water is pumped from a well, through the heat pump, and then discharged back to the earth or an adjacent well. This can reduce initial expenses and provide greater efficiency if groundwater is abundant and reliable.

Water quality and supply needs to be monitored, as minerals or debris can clog components. Routine water level and quality inspections ensure the system functions efficiently. Open loops might not be fit for locations with severe water regulations or limited groundwater.

4. Core Components

A geothermal system requires an indoor unit (heat pump), ground loop and distribution of heat, such as ducts or radiant floors. The heat exchanger is crucial—it allows the loop fluid to exchange heat with the building’s air or water. Circulation pumps circulate the liquid, and control systems fine-tune the performance.

Selecting hard, quality components counts for extended life and exceptional performance. Control systems assist with optimizing the flow and temperature, ensuring the system performs well year-round.

Design Considerations

Planning a geothermal heat loop system requires close attention to site conditions, system size, and feasibility with existing heating and cooling systems. These decisions impact system performance, price, and longevity.

Geology

Local geology, of course. Soil type, rock formations and groundwater can alter the efficiency of the ground loop. For instance, clay soils tend to retain heat more than dry sand. Rocks that are highly thermally conductive, such as granite, allow heat to flow more freely than shale or limestone.

A geological survey assists in locating the optimal loop type for the site. Surveys test for solid ground, aquifers and heat. In places where the groundwater is high, open-loop could be viable, but it has to be good water. Closed horizontal or vertical loops in dry locations are safer. Thermal conductivity data from the survey aids in selecting the appropriate heat exchanger.

Different ground water temperatures and levels can be an issue. High water tables can increase heat transfer but can lead to drilling or flooding complications. Low water tables would restrict loop alternatives. All of this needs to be considered before you shovel begins.

Sizing

Correct fit is critical. System size is based on building size, insulation, number of rooms and local climate. Heat loss and gain calculations provide an estimate of the heating and cooling energy requirements. This properly sizes the loop field and heat pump to the actual demands of the structure.

To size the loop field, designers anticipate a minimum entering water temperature (EWT) of 30°F, even in inclement weather. For horizontal loops, trenches run 1.2 to 1.8 meters deep and 3 meters apart. Vertical boreholes drilled 45-90 meters deep per ton of heating or cooling. An oversized system is more expensive and short-cycles, shortening its life. A too small one can’t keep up and results in crappy comfort and inflated bills.

Integration

- Employ variable-speed pumps and fans and vary their output to the need, saving energy.

- Add smart thermostats for better control.

- Pair geothermal with solar panels or wind for hybrids.

- Use buffer tanks to store heat for peak times.

- Convert old duct work to function with ground-source heat pumps.

Hybrid systems interspersing geothermal, solar or wind can reduce consumption even further. For new construction, planning geothermal from the get-go simplifies setup. Older structures can be retrofitted, though this usually requires some custom work to shoehorn the loop system into the existing configuration.

Installation Realities

Installing a geothermal loop is a deliberate process. Every gig can appear slightly different, but they really all tend to go along the same trail. Below is a clear outline of what to expect:

- Site evaluation and planning. The installer begins by surveying the land, soil, and space. Sometimes, if there’s an aquifer nearby, you don’t need much land either. They then decide on the type of loop—vertical, horizontal, diagonal, or even pond/lake—that works best for the space and local guidelines.

- Drilling and trenching. For vertical loops, installers drill 10-centimeter wide holes, 6 meters apart and as deep as 120 meters. Horizontal or diagonal loops are buried in trenches. Polyethylene pipes can be installed in these holes or trenches. Other systems utilize direct exchange (DX) tech, which bypasses water wells and eliminates the requirement for a secondary loop.

- The pipes are interconnected to create a closed circuit. These loops circulate fluid that transmits heat between the earth and the building. The loops are then connected to the heat pump indoors.

- Installation and start-up. The heat pump is connected to the loop, and the installer ensures no leaks and flow. Once tested, the system is switched on and tuned for optimum results.

Hiring the right geothermal installer is crucial. They understand local codes and can take care of permits, drilling, and pipe work. They ensure the work is up to safety and efficiency standards. Taking shortcuts or employing cheap labor can result in leaks, malfunctioning systems or code violations.

There are installation realities. Hard or rocky soil can bog down drilling or increase expenses. Securing permits can be delayed based on the regulations of where you live. More confined urban areas may require inventive loop configurations, such as vertical or diagonal drillings.

The schedule for installing a geothermal system can extend from days to weeks, site and local permitting process depending. Costs are higher up front than standard HVAC, but lower energy bills can recoup the difference in 5-10 years. The underground pipes, however, typically last 25 – 50 years and require little more than a few simple checks and annual coil cleaning.

Long-Term Performance

Long-term performance for geothermal heat loop systems is a function of system design, installation and ongoing care. Performance can evolve as parts wear down, conditions drift, and users use. There are a number of variables that influence the long-term performance of these systems, such with materials selection, operational practices and climate.

| Factor | Impact on Lifespan & Performance |

|---|---|

| Installation quality | Directly affects system durability and efficiency |

| Material selection | Influences resistance to corrosion, wear, and leaks |

| Maintenance routines | Reduces breakdowns and efficiency loss |

| User knowledge | Impacts proper operation and longevity |

| Climate and soil conditions | May stress or support stable operation |

| Manufacturer support | Ensures access to parts and technical help |

Durability

Pipe and manifolds in geothermal loops are typically either high density polyethylene (HDPE) or cross-linked polyethylene (PEX). These selections aid the system to stand fast against corrosion and cracks, facilitating lifetimes often lasting 50 years or longer. Heat pumps themselves have sealed compressors and copper coils that often last 20–25 years with proper maintenance.

How you install the system is just as important as what it’s made of. Proper trench depth, backfill material and fusion welding are key steps that stop leaks and keep pipes safe from shifting soil or water. Good installers, implementing best practices, can be the difference between a 20 year loop and a 100 year loop. Continuous monitoring through flow meters, temperature sensors and pressure gauges lets you detect minor issues before they develop into expensive breakdowns.

Trusted-brand warranties can take care of defects or premature breakdowns, but they indicate who the makers backing their goods. Some provide 25 years for loops and a few years for pumps.

Maintenance

- Inspect heat exchanger and loop connections for leaks or pressure drops semi-annually.

- Clean or change air filters monthly.

- Check pumps, fans and electrical contacts for wear.

- Test antifreeze solution and refill if below recommended levels.

Trained technicians inspections can catch motor wear, tiny leaks, or control faults. This sort of servicing–undertaken annually–can detect a decline in SPF or COP early. Homeowners should monitor system alerts, inspect thermostats, and remove debris from outdoor units as necessary.

Proactive care helps slow the standard 6–26% performance decline experienced during the first ten years.

Optimization

Tuning the system to local climate and building demands increases efficiency. Smart controls can adjust pump speeds and cycle durations. Thermal storage, such as a buffer tank, smoothes loads. User training—or at least a good manual—enables people to detect problems early and operate the system correctly.

Real-time monitoring, with data logs and energy meters, can reveal when the SPF or COP begin to decline. This feedback allows users or service professionals to adjust settings or replace aging components before comfort dips or energy bills rise.

Financial & Environmental Impact

Geothermal heat loop systems revolutionize the way we view both our finances and our planet in the context of heating and cooling. Unlike traditional methods, like gas or electric heating, geothermal systems tap into the consistent temperature of the earth to heat and cool structures. This is how you achieve big savings over time and a much smaller footprint on the environment. Below is a simple table to show the main cost and environmental differences between geothermal heating and more common heating systems:

| Feature | Geothermal System | Traditional Heating System |

|---|---|---|

| Upfront Cost | High | Medium to High |

| Operating Cost | Low | High |

| Payback Period | 5–10 years | Not applicable |

| Greenhouse Gas Emissions | Very low | High |

| Energy Use (per 100,000 homes/year) | 799 million kWh less | Much higher |

| Oil Use (per 100,000 homes/year) | 2.15 million barrels less | No reduction |

| Maintenance Needs | Low | Medium to High |

In addition to the financial benefits, switching to geothermal energy slashes greenhouse gas emissions, which is an enormous win for the climate. For every home or business that switches, the carbon footprint decreases. In large quantities, say 100,000 homes, that’s savings of nearly 799 million kilowatt hours of electricity annually and a distinct decline in oil consumption. This allows cities and nations reduce fossil fuels and increases energy security, which is important as energy prices can fluctuate wildly.

The governments provide assistance, too, to defray the initial investment, in the form of rebates or tax credits for both residences and businesses. These incentives can make a significant impact with the start-up cost, assisting more individuals to gain access to geothermal systems. Due to a lower cost to run and the minimal care these systems require, they end up paying for themselves in under a decade. That’s a smart strategy for saving over a long period.

Geothermal can help buildings achieve green labels such as LEED, which resonate with builders and owners who care about green spaces. With less damage throughout and post construction, it’s a victory for the pocketbook and the planet.

Future Trajectory

Geothermal heat loop systems are catching on as anyone who’s seeking a clean way to heat and cool their homes and offices. These systems utilize the geothermal heat year-round and can operate throughout the entire year. Now, this isn’t a new concept, but recent advances in drilling and heat exchange design have made them more attractive globally. Still, the future is defined by both potential and practical constraints.

Innovations in geothermal technology are emerging from the energy and oil and gas industries. Closed-loop systems are more environment-friendly because they don’t have to pipe fluids to the surface, minimizing the chances of leaks. Drilling, even with state-of-the-art equipment, is not easy. In oil and gas, wells go over budget and can fail, so those very same risks are in play here. A few of them are optimistic that costs will decline and performance will improve quickly, but that’s optimism bias—folks tend to underestimate the time and expense required for actual improvements. Specialists say it could take an additional decade earlier than these techniques can match wind or photo voltaic on value.

City and rural adoption will hinge on local requirements and ground conditions. Urban locations can utilize them to heat or cool multiple buildings simultaneously, as in district heating networks. Rural locations could utilize them for farms or small towns. Not all places are suitable for geothermal loops. You require proper rocks beneath you and have to be proximate to the source of heat demand. This restricts where these systems can travel.

Exploration is essential to making geothermal more widespread. New materials, smarter controls and better drilling may assist. Risk remains. Shifting subterranean pressure can create mini-quakes, called induced seismicity. This requires thoughtful safeguards.

The biggest stumbling blocks are expense, bureaucracy, and location restrictions. Drilling and utilization of geothermal energy is governed by nation-specific regulations, which could be cumbersome and restrictive. The most immediate value of closed-loop systems is for heating, not generating power, because the economics are better.

Conclusion

Geothermal heat loop systems tap into that consistent ground heat to warm and cool your home or building. Consumers choose these systems for reduced bills and reduced maintenance concerns. They function to reduce energy consumption and reduce the carbon footprint. There’s a big initial investment, but consistent savings begin immediately and extend for years. Innovations like new materials and geothermal heat loop systems keep pushing the field forward, transforming these systems from niche to a real choice for more places and budgets. Homeowners, builders, and city planners now receive actual data and specific actions toward making intelligent selections. To find out more or see if a geothermal system suits you, contact a local specialist or energy organization. Begin with reality, balance your objectives and discover what is optimal for your room and wallet.

Frequently Asked Questions

What is a geothermal heat loop system?

A geothermal heat loop system takes advantage of the constant temperature beneath the earth’s surface to heat or cool structures. It pumps a liquid through subterranean piping, exchanging heat with the soil and your home.

How long does a geothermal heat loop system last?

The majority of geothermal heat loops systems are in service for more than 25 years. These loops can run 50 years or more with little maintenance.

What are the main benefits of geothermal heat loop systems?

Geothermal systems are energy efficient, cutting down on greenhouse gas emissions and energy bills. They need less maintenance than conventional heating and cooling systems.

Are geothermal heat loop systems suitable for all climates?

Yes, geothermal systems work in all climates. While the air temperature can fluctuate drastically throughout the seasons, the ground below remains at a relatively constant temperature, which allows the system to provide excellent efficiencies in both hot and cold climates.

What factors affect the cost of installing a geothermal heat loop system?

Prices vary according to property size, soil conditions, loop type, and depth of installation. Upfront costs are higher than conventional systems, but energy savings offset these over time.

Do geothermal systems require a lot of maintenance?

Geothermal heat loop systems require minimal maintenance. Periodic inspections of the system’s internal components maintain efficiency. Underground loops seldom require fixing.

How do geothermal heat loop systems impact the environment?

These systems utilize renewable energy from the earth, minimizing dependence on fossil fuels and decreasing carbon emissions. They’re small environmental footprint as well.

Send Buck a voice message!

Send Buck a voice message!