Investing in 3D-Printed Construction: Transforming the Housing Market

Key Takeaways

- 3D-printed construction leverages advanced technology and industry innovations to automate and streamline the building process. This new method produces faster and more accurate results than conventional approaches. This innovation could be the answer to the long-term housing crisis.

- Some researchers have already tapped into more conventional materials, such as concrete and recycled plastics, for 3D printing. They’re big on creating new, creative methods that improve sustainability and durability.

- Investing in 3D-printed buildings can address global housing shortages by enabling affordable, rapid housing solutions, especially in areas affected by disasters or high demand.

- 3D printing offers compelling benefits. It drastically reduces labor costs, improves construction speed, and provides design flexibility—advantages that would be extremely attractive to developers and future homeowners alike.

- Challenges such as regulatory hurdles, material limitations, and public perception must be addressed to fully realize the potential of 3D-printed housing. Industry stakeholder collaboration is key. Collaboration between industry stakeholders will be crucial.

- The market is exploding thanks in part to technology breakthroughs and interoperability with smart home systems. This wave of opportunity in 3D-printed construction creates a once-in-a-lifetime opportunity for investors and developers.

Investing in 3D-printed construction is revolutionizing the housing market by providing quicker, cheaper, and more environmentally friendly building methods. It’s an exciting new process that employs cutting-edge technology to 3D-print homes, layer by layer, drastically lowering material waste and labor costs.

With the ability to build entire structures in just days, 3D printing addresses housing shortages and provides affordable options for communities in need. This rapid construction method not only meets urgent housing demands but also offers a solution to rising costs in traditional building practices.

With personalized designs, sustainable materials and more, this approach paves the way for innovative and functional solutions to today’s urban habitats. The flexibility in design allows for customization that can cater to individual needs and preferences, making homes more accessible and appealing.

As the technology progresses, it’s gaining further steam with investors eager to fund the latest innovations in the real estate market. This growing interest from investors signals a promising future for 3D-printed construction, potentially transforming how we think about housing and urban development.

What is 3D-Printed Construction?

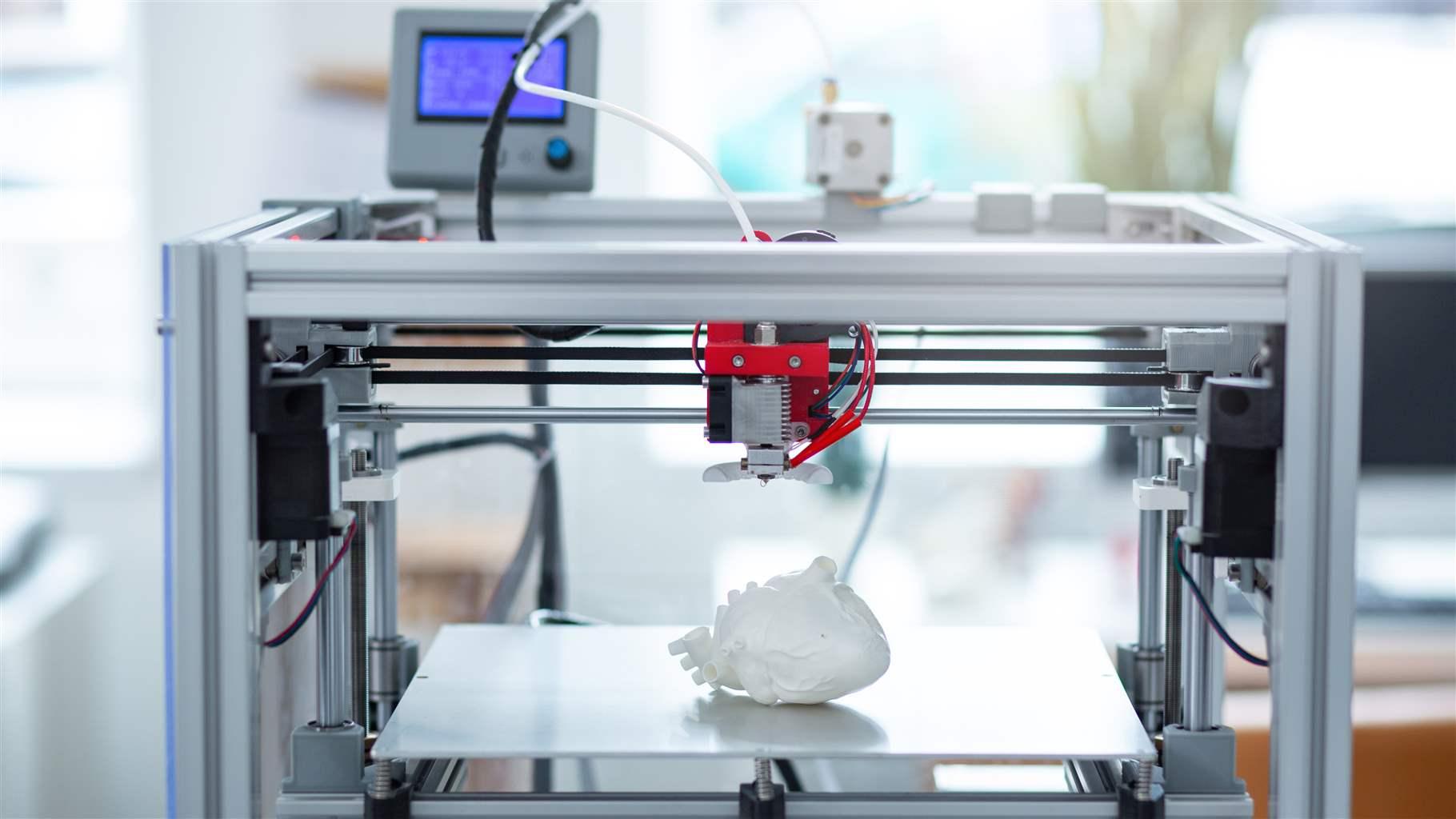

Three-dimensional (3D)-printed construction is an innovative approach in which industrial-sized printers construct components of buildings through an additive process. These printers, controlled by digital blueprints and robotic arms, guarantee precision and consistency in the production process. This new automated approach promises to fundamentally change how we build.

In fact, 3D-printing technology enables the rapid, cost-effective production of all walls, foundations and even entire structures in a fraction of the time it takes using conventional construction methods.

Definition and Basic Process

The journey starts with a digital blueprint, often created in specialized building design software. First, the design model is converted into instructions for the printer. Next, the printer deposits concrete or other specialized mixtures, layer by layer, with extreme accuracy.

By building up the structure layer by layer, 3D-printed construction ensures structural integrity while providing the desired strength and stability. Robotic automation is the key element, expediting repetitive tasks and mitigating human error.

In addition, a small crew of only 3-4 individuals can effectively build a 3D-printed home. Generally, this approach decreases labor costs and construction time by a major margin.

Materials Used in 3D Printing

Though concrete is by far the most material of choice, mixtures that include recycled plastics and various other additives are more popularizing. These new materials, besides increasing a project’s durability, increase its sustainability.

To address this issue, researchers are looking into alternatives, such as biodegradable composites, which would only further reduce the environmental impact of 3D-printed construction. As an example, SQ4D’s material costs for a home would be reduced to only $6,000.

This underscores the remarkable cost efficiency they’ve achieved with their approach.

Potential Impact on Housing Market

The advancements in 3D printing technology involve a lot of potential when it comes to addressing global housing shortages by creating affordable homes faster. Basic homes start at $10,000 to $50,000 and could be in use for 50 to 100 years.

This is especially important in disaster areas, where the need for quickly deployed long-lasting shelters is paramount. Our urban communities win as well. Technology that promotes smart, scalable, sustainable community development is a boon to our existing urban areas.

Benefits of Investing in 3D Printing

Here are just a few examples of how investing in 3D printed construction meets an impressive set of fiscal and social benefits. Delivering everything from shorter project timelines to eco-friendly solutions, this advanced innovation is solving urgent housing needs and creating financially rewarding prospects for investors.

1. Faster Construction Times

With 3D printing, construction time is drastically speedier, allowing homes to be move-in ready within days instead of months. The time savings are considerable. A 500-square-foot home can be printed in as little as 24 hours.

This quick turnaround can make all the difference when urgent housing needs arise, whether in regions already battling shortages or those struck by natural disasters. By reducing construction times by up to 70%, developers can deliver housing solutions more efficiently, avoiding delays commonly associated with traditional methods.

2. Reduced Labor Costs

Thanks to 3D printing, labor costs are cut by almost half. Automated processes reduce the requirement for large replacement work crews, resulting in significant cost savings.

These cuts are one step closer to making affordable housing projects more feasible, especially in those communities that have been historically underserved. The savings are not just in developers’ pockets—lower costs make for more affordable housing prices for prospective buyers.

This makes it a win-win proposition for communities and investors alike.

3. Design Flexibility and Innovation

With 3D printing comes design freedom like never seen before. Through exploration of complex forms or tailored unique elements, architects don’t have to raise the bottom line to do this.

Buildings can feature curved walls, built-in furniture, or completely unconventional layouts, providing an opportunity for expanded creativity and modern minimalist/artistic aesthetics.

4. Sustainable Building Practices

This method eliminates material waste by as much as 60%, with no excess materials used beyond what is needed. A number of projects use recycled or sustainable materials, reducing impacts on the environment.

With environmental practices closely related to green initiatives, 3D printing provides a sustainable option to conventional construction.

5. Customization and Personalization

Customized designs are a major benefit. Buyers work with architects to customize floor plans and finishes, designing living environments suited to their individual lifestyles.

Distinctive, one-of-a-kind residences are in demand, appealing to today’s most sought-after buyers.

Challenges of 3D-Printed Construction

3D-printed construction presents amazing opportunities. Unfortunately, there are still a number of challenges that we need to address before it can be a widely-adopted tool in the affordable housing toolbox. These challenges range from regulatory structures, material constraints, expenses, and societal attitudes, each needing a harmonized approach to break through.

Regulatory Hurdles and Building Codes

These homes cannot be adopted so liberally yet as the current building regulations pose a daunting challenge to the adoption of 3D-printed homes. Integrating this technology into existing U.S. Building codes remains a major hurdle. Traditional codes were never designed with these new methods in mind, leading to a daunting transition.

The International Code Council’s Appendix AW and UL 3401 standard are major steps forward. While these provisions are helpful, we need more robust national level holistic updates to begin better accommodating innovative practices. Advocacy from industry leaders and policymakers will be critical in shaping a regulatory environment that supports 3D construction while ensuring safety and consistency.

Material Limitations and Durability

Additionally, since most 3D-printed homes use concrete, which is quicker and cost-effective, it poses complications in strength and long-term durability. Concerns about how resilient these materials would be under extreme weather or seismic activity remain, leaving doubts in these stakeholders’ minds.

Current investigations have pivoted towards use of other sustainable materials such as composites and reinforced polymers. This work seeks to address current issues and increase the diversity of feasible construction solutions.

Initial Investment Costs

Such high upfront costs for 3D printing equipment and infrastructure present financial barriers for builders and developers. For smaller firms, these costs can preclude entry into the market without outside investment.

Their potential solutions span government incentives, private investments, or nonprofit grants that collectively will help offset these initial expenditures.

Public Perception and Acceptance

Even with all its benefits, public understanding of 3D-printed homes is lacking. Most single family homeowners are unaware of how this technology can save them hundreds of dollars.

It’s been instrumental in addressing positive housing emergencies, such as the U.S.’s deficit of 4.5 million units. Educational campaigns and high-profile proof-of-concept projects, like Dubai’s record-breaking 3D-printed building, are working to actively build that trust. Beyond that, they educate the greater market.

Cost-Effectiveness of 3D-Printed Housing

Investing in 3D-printed construction would be a missed opportunity. It directly addresses the emerging challenges of affordability and efficiency in our housing market. It’s the technology itself that transforms cost structures, making it an appealing option for both individual homeowners and real estate investors.

Compare Construction Costs

| Category | 3D-Printed Homes | Traditional Homes |

|---|---|---|

| Labor Costs | Reduced due to automation | Higher due to skilled labor |

| Material Costs | Optimized, less waste | Higher with traditional methods |

| Construction Time | 1-2 days for exterior modules | Several months |

The major cost savings come primarily from automation and material efficiency. For example, the removal of skilled labor for much of the printing process lowers labor expenses tremendously. Efficient material usage reduces waste, providing additional cost savings.

Cities that are experiencing high labor costs see the largest benefits from implementing 3D printing. At the same time, the lure of savings on materials knows no geographic boundaries.

Analyze Long-Term Savings

The cost savings of 3D-printed homes don’t stop once the keys are in your hand. Their designs sometimes focus on energy efficiency as well, saving future tenants money on heating and cooling bills. Higher longevity and lower maintenance is another attractive benefit, as the modular nature of printing guarantees the same quality and lasting impression.

Taken together, these factors create a more affordable and sustainable homeownership experience over time.

Discuss Economies of Scale

As 3D printing technology rapidly matures, economies of scale will be realized through mass production. When printing homes in bulk, the cost per unit decreases, thus making large-scale developments more financially feasible.

With improved speed of production, a single-story exterior could be completed in a day. This ability makes 3D printing a potential game-changer for both scale and need for affordable housing.

Current Trends and Future Projections

One innovation currently getting a lot of buzz is 3D-printed construction technologies. The combination of new materials and machinery, greater demand from developers and individual homeowners, are propelling this trend. This section covers major trends and projections that are defining the future of the housing market through 3D printing.

Market Growth and Adoption Rates

The 3D printing construction market is HOT right now! According to the release, experts project the composite segment to increase with a stunning CAGR of more than 112.5% throughout the forecast period. By 2024, the construction segment will likely lead the market, representing 72.1% of total revenue.

North America, especially, is projected to experience the most explosive growth from 2025-2030. Greater public and institutional demand for sustainable solutions is fueling this momentum. Equally important, though, is the ability to avoid supply chain disruption.

The concrete type led the market with a 34.8% revenue share in 2024. Its combined affordability and efficiency make it a top choice for consumers. These major investments by Khosla Ventures and KB-Badgers make it very clear that these firms see confidence and promise in this evolving sector.

Technological Advancements

Technological breakthroughs, most notably in 3D printing, are rapidly changing the construction landscape. Expect powder bonding systems to make a step change advancement from 2025 to 2030. These innovations will improve structural performance and reduce material waste.

Others, like XtreeE, are taking steps to broaden access globally with three new regional units just launched in 2023 to speed localized, customizable construction processes. Research and development is ongoing, focusing especially on improving machinery and composite material technologies to increase durability, efficiency, and wear resistance.

Impact on Housing Affordability

Affordability is perhaps the most head-turning advantage of 3D-printed structures. By simplifying labor and material costs, this innovative technology helps deliver more affordable housing, lowering barriers for first-time home buyers.

One of the most heartwarming success stories is the 3D-printed home of April Stringfield in Williamsburg, Va., which was completed right before Christmas. Through this project, associated homes and community will demonstrate the possibility of delivering high-quality, affordable homes on time and on budget.

Integration with Smart Home Technology

One trend that we are seeing more of is these homes being designed specifically to adopt smart technology. Smart attractions and modern touches such as automated lighting and energy-efficient systems are attractive to tech-savvy buyers in addition to providing future savings.

The flexibility of 3D printing allows for customized designs that incorporate eco-friendly amenities, aligning with the growing demand for sustainable living.

Key Players and Innovators

3D-printed construction is revolutionizing the housing industry. It offers timely, creative solutions that address affordability, sustainability and the quickly increasing need for new homes. Central to this change are the key players and innovators—companies, entrepreneurs, and thinkers—who are developing new technologies, collaborations and ground-breaking business models.

Leading Companies in the Field

Based in Austin, ICON has pioneered 3D-printed homes in the U.S., completing projects in cities like Austin and Nacogdoches, Texas. Their work brings together advanced robotics and impact-resistant, protective proprietary materials that form high-performing, durable housing.

ICON collaborated with New Story to construct the world’s first 3D-printed housing community in Tabasco, Mexico, benefiting families in extreme poverty.

This Chinese company made headlines in 2015 by constructing a five-story apartment block, the tallest 3D-printed structure globally, using cutting-edge large-scale printers. Their work shows that 3D printing can be scalable to multi-unit housing – an extremely important aspect for inclusion in their approach.

Focused on Africa, 14Trees showcased 3D printing’s potential by building ten homes in Kenya. Their stories underscore the technology’s potential to help solve housing crises in areas of extreme demand.

Innovative Business Models

Creators from companies like Gene Eidelman’s J Print Homes are transforming the way we build with more sustainable, efficient, cost-effective 3D printing. Eidelman’s commitment goes beyond his own productions, allocating 10-20% of production to nonprofit and government projects that further the affordable housing and homelessness solutions.

These models go beyond focusing on accessibility to feature the scalability and environmental advantages of 3D printing in construction.

Case Studies of Successful Projects

ICON and New Story’s community in Tabasco is a perfect illustration of our technology’s potential to deliver quality, durable, low-cost housing to vulnerable families.

Likewise, 14Trees’ work in Kenya demonstrates how this technology develops local capabilities and addresses urgent housing needs in communities.

Risks and Returns on Investment

Investing in this disruptive and cutting-edge industry is exciting—but risky. One of the biggest risks against this return is that the technology is still very new. The market is set for amazing expansion—projected CAGR of 70.0% from 2024-2031. It might hit a jaw-dropping $1,436.2 million! Yet, there’s some uncertainty due to the slow pace of industry adoption.

Of course, technical failures during construction, unforeseen regulatory hurdles, and a pipeline of limited skilled labor can all change the equation on planned project timelines and cost. Market volatility creates unknowns, particularly where rapid changes in material costs or demand for housing affect overall margins.

On the returns side, that’s one of the big attractions to 3D-printed homes is cost-efficient trait. The average house—from the argument above it can be as little as $10,000—much cheaper than all the traditional approaches. This affordability creates unique opportunities for investors.

Given the potential for quicker construction timelines, they can now attract investment from markets seeking affordable housing and smart cities opportunities. Long-term gains are likely as the market matures, particularly for those who adopt data-driven strategies, as emphasized by industry experts like Tom Ferry.

Risk mitigation requires robust financial contingency planning and flexibility to pivot. All financial analyses should use metrics such as return on investment (ROI), projected cash flow, and payback periods for each proposed project. Any investor should be able to obtain full-blown insurance for any liabilities.

Getting policies for new approaches is often difficult, so they need to be plugged in. Building trust and long-term relationships within the real estate ecosystem is equally crucial, as highlighted by professionals like Ryan Serhant. Success lies in balancing innovative opportunities with calculated risk, ensuring sustainable growth.

Legal and Contractual Aspects

With 3D-printed construction now drastically changing the housing market, getting a better sense of this legal and contractual landscape is key. From negotiating contracts to protecting intellectual property and meeting regulatory requirements, careful planning ensures smoother project execution and safeguards stakeholder interests.

Contract Negotiation Strategies

Robust contract negotiation is key to managing expectations in 3D-printed construction. Here are strategies to consider:

- Define project scope and timelines clearly to ensure accountability.

- Insert clauses related to quality of materials, actual 3D printer performance, and upkeep.

- Specify intellectual property ownership for custom designs and innovations.

- Include alternative dispute resolution approaches, like mediation or arbitration, to resolve issues quickly.

Transparency and open communication go a long way. For instance, setting expectations on potential delays from technology-specific challenges early on can establish trust and lower the risk of frustration later on.

Intellectual Property Protection

The novelty presented by 3D-printed designs requires strong intellectual property (IP) protections. Innovations such as the U.S. Army’s patented concrete alternative underscore the need for safeguarding.

This can be done through strategies such as filing patents for proprietary materials and ensuring copyrights for original designs. Legal difficulties lie in distinguishing originality, the Spanish Supreme Court has observed.

Collaborating with IP attorneys ensures compliance with evolving laws while protecting creative contributions.

Compliance with Regulations

Compliance with environmental and other regulatory requirements are essential to a successful project. Local building codes set the rules of the road for construction.

In Austin, Texas, these codes permitted the construction of the region’s first fully 3D-printed domicile. International efforts, such as Dubai’s 3D printing ambitions and the Netherlands’ 3D-printed bridge, drive home the point of worldwide adoption.

Failure to comply exposes the entity to the threat of delay, monetary fines, or damage to its reputation. Keeping abreast of these guidelines, like those highlighted by WIPO, is key to averting such dangers.

Environmental Sustainability

Convergence of 3D-printed construction with the housing market presents tremendous prospects to help or hurt environmental sustainability. This technological innovation disrupts decades of conventional, inefficient building practices. It focuses on producing more with less, consuming fewer resources, and introducing environmentally friendly materials to the construction process.

Reduced Waste and Emissions

3D printing in construction reduces environmental waste by allowing precise material usage. Unlike conventional methods, which often result in excess debris, 3D-printed projects use only the required amount of material, significantly cutting down on waste.

It’s predicted that construction will account for as much as 2.2 billion tons of waste worldwide by 2025. After all, building materials will constitute as much as half that waste, making this change incredibly important. Mighty Buildings, however, is a company that’s already accomplished near-zero waste in their operations, paving the way for the industry.

Waste reduction means less energy is used in production, leading to lower greenhouse gas emissions. These practices do double duty by reducing a project’s carbon footprint while showcasing how creative approaches can solve our environmental dilemmas.

Use of Eco-Friendly Materials

Adding sustainable materials into the mix looks to multiply the environmental benefits of 3D-printed construction. Take, for example, Mighty Buildings’ use of panels created with 60% recycled content, an example of the closed-loop resource use industry should strive to achieve.

Sustainable materials, including bio-based composites or recycled plastics, increase the durability and energy efficiency of structures. These materials provide tangible and active support for sustainability goals. They further optimize climate-resilient designs that better withstand the impacts of extreme weather events like hurricanes and earthquakes.

Contribution to Green Building

In many ways, 3D-printed homes are at the forefront of new green building practices. In addition to saving water consumption by as much as 99%, they meet LEED and Green Building construction standards while furthering overall housing stock needs.

These affordable prefab homes lower operational costs while adding 14% to a home’s construction time. They are an effective, attainable, and sustainable response to our housing crisis.

Conclusion

Investing in 3D-printed construction provides an opportunity to support innovation while saving the bottom line and protecting our environment. It marries innovative technology with real world uses, making our housing stock more affordable and available to the people who truly need it. This method minimizes excess material, speeds up the time it takes to create a building, and makes way for innovative patterns. Despite regulatory challenges and the slow pace of market adoption, this opportunity for massive growth far exceeds the risk for many investors.

With the housing market being fundamentally undergoing a revolution, 3D printing leading the charge. Following this burgeoning market and thinking strategically about it will position you to make better informed, holistic decisions that will benefit your community. Whether you’re excited about its green credentials, affordability, or long-term possibilities, 3D-printed construction is creating a dynamic change to the market right before our eyes. If so, now’s the time to explore how it could fit into your investment goals.

Frequently Asked Questions

What is 3D-printed construction?

3D-printed construction refers to the innovative technology of using large scale, industrial printers to produce construction components layer by layer, typically in concrete. It’s an exciting alternative model that both accelerates the construction process, lowers costs, and lessens building material waste.

Why should I invest in 3D-printed construction?

Investing in 3D-printed construction has tremendous growth potential. It’s revolutionizing the housing market by reducing costs, increasing efficiency, and combating housing shortages worldwide. These early investors are often rewarded with major returns as the technology goes to scale.

How cost-effective is 3D-printed housing?

3D-printed housing has the potential to save up to 50% in construction costs over traditional methods. Reduced build times and material waste both play a role in its cost-efficiency.

What are the environmental benefits of 3D-printed construction?

3D-printed construction minimizes waste, incorporates sustainable materials, and significantly lowers carbon emissions. Its resource-efficient methodology advances green building practices and responds to widespread environmental issues plaguing the housing sector.

What challenges does 3D-printed construction face?

Challenges are plentiful and entrenched, ranging from regulatory approval to lack of material availability and high initial setup costs. To start there’s a learning curve, both for engineers and contractors who will be implementing this newly released tech.

Who are the key players in 3D-printed construction?

Key innovators in the space thus far are companies like ICON, Apis Cor and Mighty Buildings. From leading edge technology to successful large-scale experimental projects, these pioneers are revolutionizing the industry as we speak.

Are there legal risks involved in 3D-printed construction?

Sure, there are legal risks such as ambiguous building codes, warranty claims and IP concerns, to name a few. To avoid these pitfalls, investors ought to obtain legal guidance to traverse these unique complexities.

Send Buck a voice message!

Send Buck a voice message!